In our last article, we covered how salt spray tests help us understand rust resistance. This time, we’re diving deeper into the process that keeps our parcel boxes looking sharp and standing strong for years — powder coating.

If you’ve ever seen a rusty, faded, or peeling mailbox, chances are it didn’t go through proper pre-treatment or wasn’t coated correctly. Powder coating isn’t just about color — it’s the frontline defense against corrosion, UV damage, and aging.

Here’s how we make sure our coatings go the distance.

Before any coating goes on, we start with a deep clean. Why? Because untreated surfaces often carry dust, oil, and manufacturing residue, which can ruin the coating — causing bubbling, flaking, or that dreaded "orange peel" texture.

Here’s our 3-step prep process:

Surface dusting: We use air guns and clean cloths to wipe away loose particles.

Degreasing rinse: The panels go through an alkaline spray bath to remove oils and residues.

Final water rinse: A clean water rinse ensures a contaminant-free surface, ready for coating.

Only then does the metal enter our powder coating line.

Once the surface is prepped, we apply the powder and then run multiple tests to ensure performance — not just appearance.

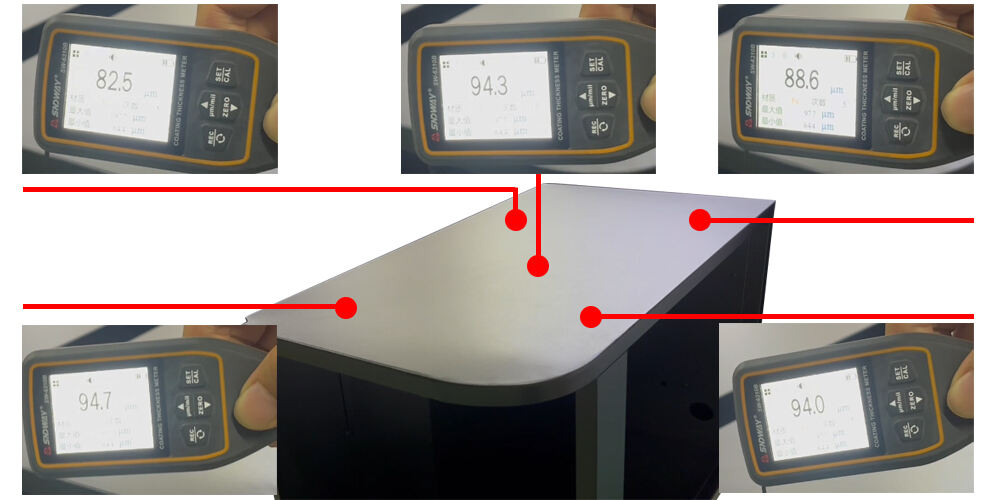

Every box is checked for coating thickness. While typical powder coatings range from 60–80μm, we target a slightly thicker 80–100μm layer to enhance long-term durability. This increased thickness is necessary because our products also undergo an additional electrophoretic (e-coating) layer beneath the powder coating, providing a dual-layer protection system.

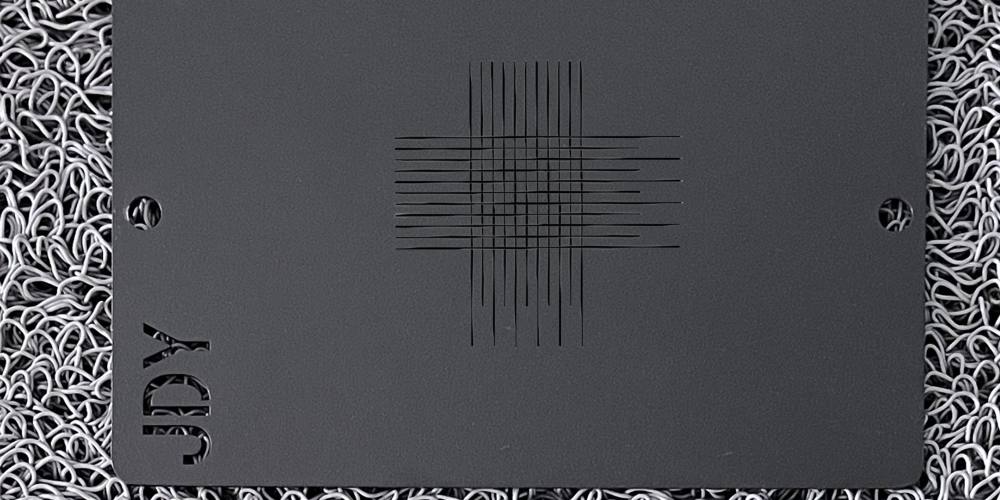

This test checks how well the coating adheres to the surface. We cut a grid into the coating and apply tape to see if it peels. Strong adhesion means the box will resist flaking or cracking even in rough handling.

We used electrophoretic coating first, and then white textured powder spraying for 500 hours salt spray test results.

Result :

Cold-rolled: rusted.

Galvanized: some peeling, but no rust.

Aluzinc: remained intact.

Already covered in our previous article, this test simulates years of exposure to salt and moisture to verify corrosion resistance.

We place finished boxes in outdoor environments to monitor how they age under real weather.

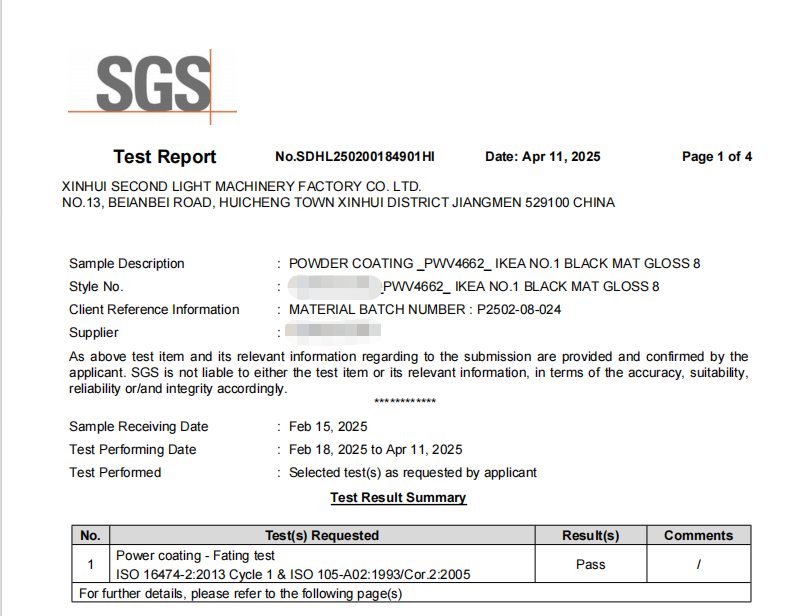

We also conduct 1,000-hour artificial light aging tests through third-party labs to evaluate how well the coating stands up to sun exposure and environmental wear.

Powder coating isn’t just about looks — it’s about long-term protection. Through thorough surface preparation, strict process control, and multiple quality tests, we make sure every parcel box can withstand the elements for a decade or more.

It’s why our customers trust us. And it’s why your delivery box won’t just survive the rain — it’ll survive the years.

Hot News

Hot News2025-11-10

2015-06-01

2025-06-07

2025-03-31

2025-08-30

2025-08-11