Why Parcel Boxes Rust — And What We Do About It

Quick Intro

Parcel boxes are meant to protect your deliveries, not look like they’ve been through a shipwreck. In this article, we explain why outdoor parcel boxes can rust and exactly what we’re doing to stop it.

So, what causes this? And more importantly—how can we fix it?

Outdoor parcel boxes are typically made from one of three materials:

Cold-rolled steel (CRS)

Galvanized steel

Aluzinc (galvalume) steel

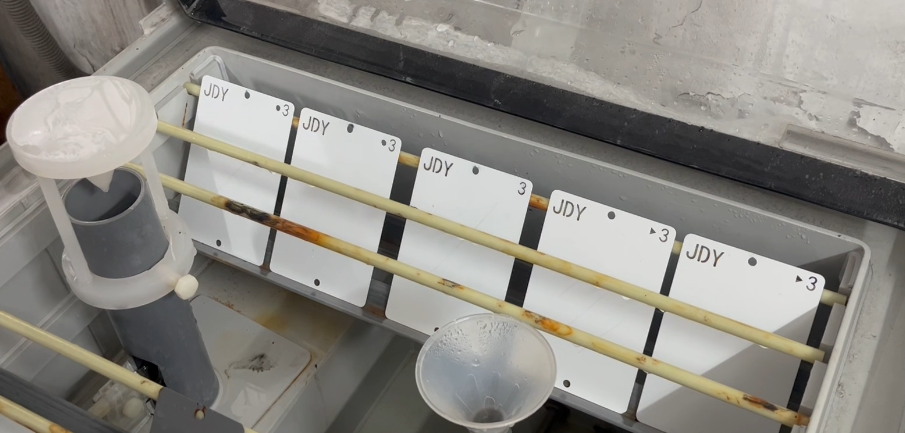

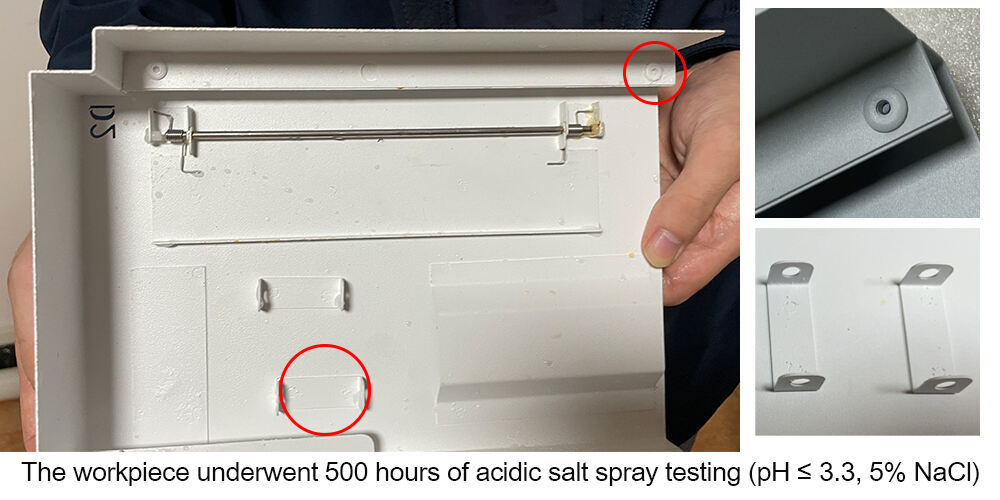

To find out how these materials handle real-world conditions, we performed a 500-hour salt spray test using a 5% NaCl solution. We tested bare materials, powder-coated surfaces, and coated surfaces that were intentionally scratched to simulate damage.

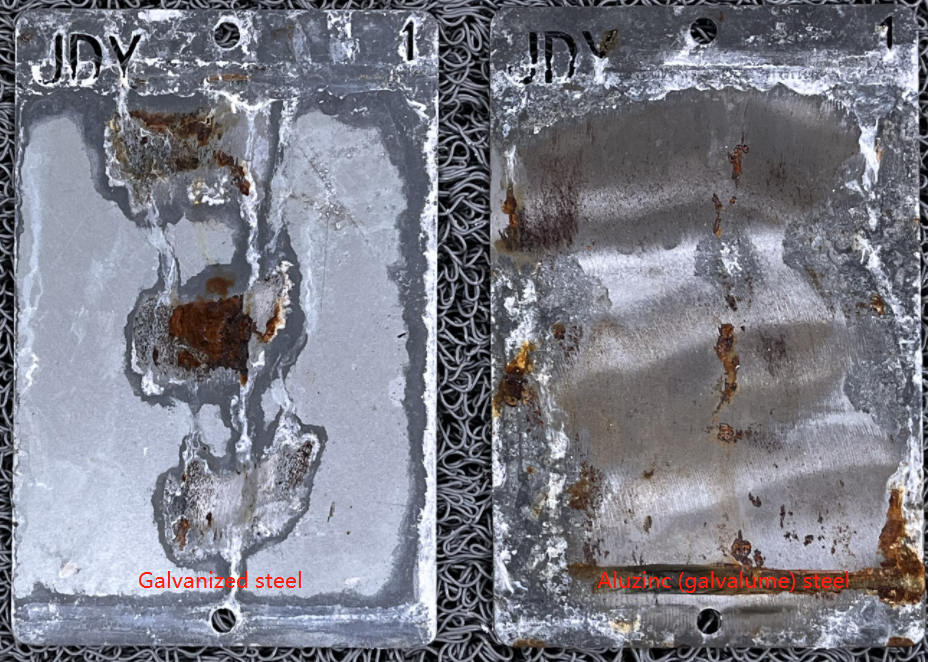

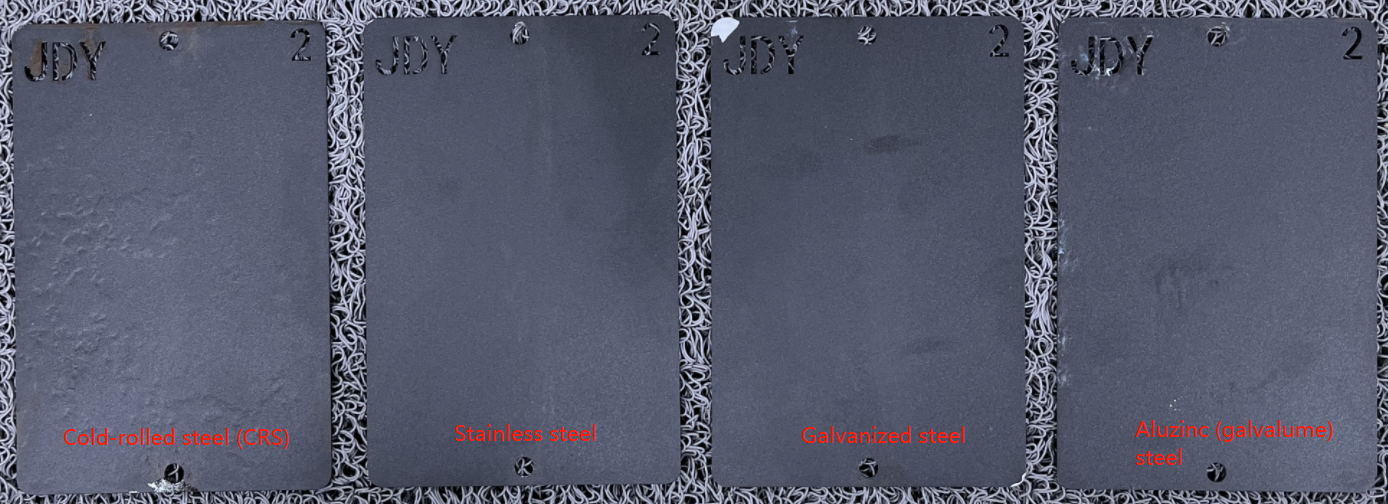

We tested cold-rolled steel, galvanized steel, and aluzinc without any protective coating.

Result: Every material rusted, especially the cold-rolled steel has corroded and cannot be distinguished.

We applied black textured powder coating on the same materials.

Result:

Cold-rolled steel showed serious rusting and heavy blistering.

Galvanized steel had minor surface flaking and small bubbles, but no visible rust.

Aluzinc steel held up best—surface mostly intact with some moderate bubbling, no rust.

This time, we applied electrophoretic coating followed by white textured powder coating. We then scratched the surface to test rust resistance.

Result (Scratched Surface):

Cold-rolled steel: severe rust at the scratch sites.

Galvanized steel: slight rust, small blisters.

Aluzinc: no rust, moderate bubbling only.

Result (Unscratched Surface):

Cold-rolled: rusted.

Galvanized: some peeling, but no rust.

Aluzinc: remained intact.

So Why Do Parcel Boxes Still Rust?

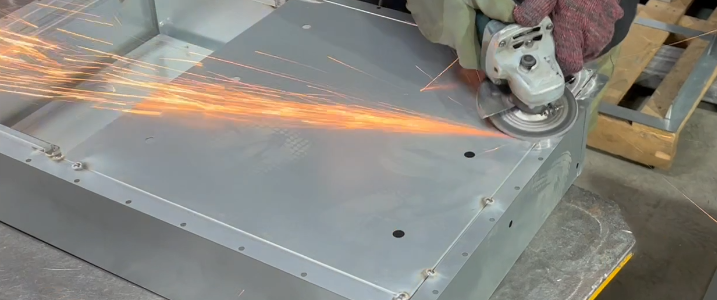

Under normal conditions, galvanized and aluzinc steel resist corrosion quite well. However, when turning them into parcel boxes, we run into a common issue: welding.

To build a durable box, multiple steel sheets must be joined together. Traditional welding causes heat distortion and leaves visible weld points. To smooth things out, these weld points are ground down—but this process damages the protective coating and exposes raw steel to air and moisture.

And that’s where rust starts.

To minimize corrosion, we've upgraded our process:

Two coating options:

Powder coating only

Electrophoretic coating + powder coating for high-end protection

Based on extensive testing, here’s what we’ve learned:

Cold-rolled steel rusts easily, even when coated.

Galvanized steel resists rust unless deeply scratched.

Aluzinc steel performs best, maintaining integrity even after damage.

By switching up our construction methods and improving surface treatments, we're building parcel boxes that stay rust-free, look sharp, and last longer—even when left outside year-round.

Hot News

Hot News2025-11-10

2015-06-01

2025-06-07

2025-03-31

2025-08-30

2025-08-11