Introduction

Imagine a world without online shopping. For those born after the 2000s, this might seem unthinkable. Yet, British inventor Michael John Aldrich revolutionized commerce in 1979 by creating the first online transaction system, bridging businesses and consumers globally. Today, parcel boxes are the unsung heroes of this revolution, protecting deliveries from rain, theft, and damage when no one is home.

This guide will help you navigate the complexities of parcel box manufacturing, from material selection to production processes, ensuring your design balances durability, cost, and aesthetics.

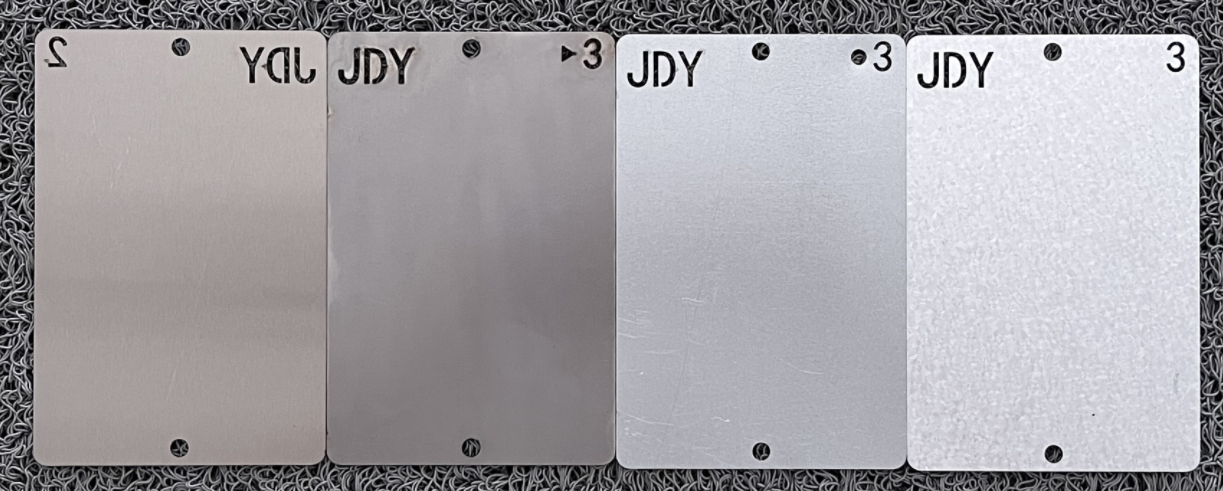

Choosing the right metal material is critical for functionality and longevity. Below, we analyze common options, focusing on their inherent properties (excluding post-processing effects):

| Material | Benefits | Drawbacks |

| Aluminum Alloy | 1. High corrosion resistance (natural oxide layer). 2. Lightweight (low density). 3. Excellent formability for complex designs. | 1. Lower tensile strength than steel; thicker panels reduce storage capacity. 2. Higher cost than mild steel. |

| Stainless Steel | 1. Superior corrosion resistance (chromium/nickel alloys). 2. High structural strength. 3. Aesthetic appeal (smooth, glossy finish). | 1. Heavyweight increases shipping costs. 2. Expensive upfront investment. |

| Cold-Rolled Steel | 1. Cost-effective. 2. High yield strength and machinability. 3. Compatible with coatings. | 1. Prone to rust without protective coatings. 2. Limited outdoor durability. |

| Galvanized Steel | 1. Zinc coating resists corrosion. 2. Affordable for mass production. | 1. Zinc layer may peel if damaged, exposing base metal. 2. Limited lifespan in coastal/salty environments. |

| Aluminum-Zinc Steel | 1. 2-4x longer lifespan than galvanized steel. 2. Heat-reflective properties. | 1. 15-20% higher cost than galvanized steel. |

| Copper Alloy | 1. Exceptional corrosion resistance. 2. Unique aesthetic appeal. | 1. Prohibitively expensive for most applications. |

| Plastic | 1. Lightweight and moldable. 2. Low-cost for simple designs. | 1. Requires expensive molds. 2. Poor UV/impact resistance. |

Top Recommendations for Outdoor Use:

● Budget-Friendly: Galvanized or cold-rolled steel with powder coating.

● Coastal Areas: Aluminum-zinc alloy or stainless steel.

● Lightweight Needs: Aluminum alloy (ensure structural reinforcements).

Suitable for cold-rolled steel, galvanized steel, and aluminum-zinc steel.

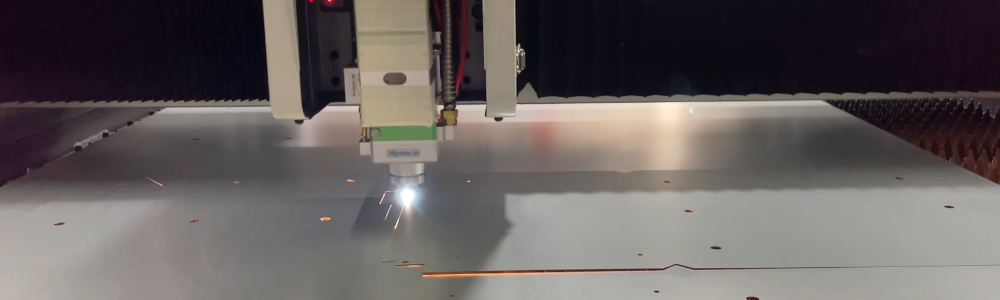

1.Laser Cutting

Process: High-power lasers vaporize metal to create precise shapes (e.g., Laser Cutout Logos, decorative patterns).

| Key Considerations | Potential Pitfalls & Solutions |

| Material thickness: ≤20mm | Blackened Edges: Caused by excessive laser power or slow speed. Fix: Optimize parameters (e.g., 3kW laser for 5mm steel at 2m/min). |

| Use nitrogen assist gas for stainless steel | Rust Formation: Exposed edges oxidize. Fix: Apply temporary anti-rust spray or prioritize powder-coated areas. |

2. CNC Punching

Process: Dies shape metal sheets into arcs, flanges, or embossed logos.

| Key Considerations | Potential Pitfalls & Solutions |

| Arc-shaped designs enhance aesthetics | High Mold Costs: Custom dies cost $2,000-$10,000. Fix: Using JDY's existing rounded top cover design. |

| Ideal for batch production | Structural Weakness in Hollow Arcs: Fix: Using detachable Arc-shaped structure or use shock-absorbent packaging.. |

Interested in learning more, JDY offers a variety of Arc-shaped in different shapes and safe transportation methods that have passed the 50cm drop box test.

3. Bending

Process: Press brakes form V/U-shaped bends with radii ≥1x material thickness.

| Key Considerations | Potential Pitfalls & Solutions |

| Automated bending for consistency | Cracking: Caused by incorrect bend radius. Fix: For 2mm steel, use ≥2mm radius. |

| Grain direction matters (avoid parallel bends) | Springback: High-strength steel may rebound 8-12°. Fix: Overbend by 2-3°. |

Case Study: Bending automation reduces production time by 40% for JDY.

4. Welding & Riveting

| Method | Pros | Cons |

| Welding | Strong, permanent bonds | Heat distortion; use skip welding. Weld zones rust if uncoated. |

| Riveting | No heat distortion, works for mixed materials | Weak if holes are misaligned. Aesthetic issues with visible rivets. |

5. Powder Coating

Process: Electrostatic spraying creates a 60-80μm protective layer.

| Step | Best Practices |

| Pre-Treatment | - Degrease (pH 9-11 alkaline cleaner). - Phosphating (2-3g/m² zinc layer). |

| Spraying | - Maintain 15-25cm distance; 50-80kV voltage. - Avoid "orange peel" by optimizing humidity. |

| Curing | - 180-200°C for 20-30 mins (use IR ovens for energy efficiency). |

Common Defects & Fixes:

● Poor Adhesion: Caused by oily residues. Fix: Conduct cross-cut tape testing (ISO 2409).

● Color Fading: Use UV-resistant powders to last 10-15 years outdoors.

Section 3: Cost-Saving Strategies

● Material: Use galvanized steel instead of stainless steel (saves 30-50%).

● Design: Standardize sizes to reduce laser cutting waste.

● Labor: Automate bending and welding for high-volume orders.

Conclusion

From laser cutting to powder coating, each step in parcel box manufacturing requires precision to balance durability and cost. By selecting the right materials and optimizing production processes, you can create high-quality parcel boxes that withstand weather, theft, and time.

● Ready to Dive Deeper? Explore our follow-up guides:

● How to Prevent Rust in Metal Parcel Boxes

Hot News

Hot News2025-11-10

2015-06-01

2025-06-07

2025-03-31

2025-08-30

2025-08-11