A real factory visit story reveals why craftsmanship, structure, and process details matter more than images when sourcing parcel boxes from China.

Last week, we welcomed another group of overseas clients to the JDY factory.

On the surface, this was nothing unusual—sampling, discussions, factory tour.

What made this visit different was one detail they casually shared with us:

“We are working with six suppliers in China. We plan to visit all of them.”

We happened to be the third stop on their itinerary.

Before arriving at JDY, these clients had already completed sampling with other suppliers. Multiple models. Multiple designs. Samples shipped overseas.

The result?

High costs. Long waiting times. And products that looked good in photos—but didn’t hold up in reality.

This is becoming increasingly common. With today’s online tools, it’s easy for suppliers to present polished images. Some products are referenced from other websites, adjusted slightly, and presented as “in-house designs.” The differences only appear after the box is in your hands—when it’s already too late.

During our discussion, we compared a U.S. mailbox model produced by JDY with a visually similar sample they had received earlier.

At first glance:

Similar shape

Similar function

Similar market positioning

But the construction told a different story.

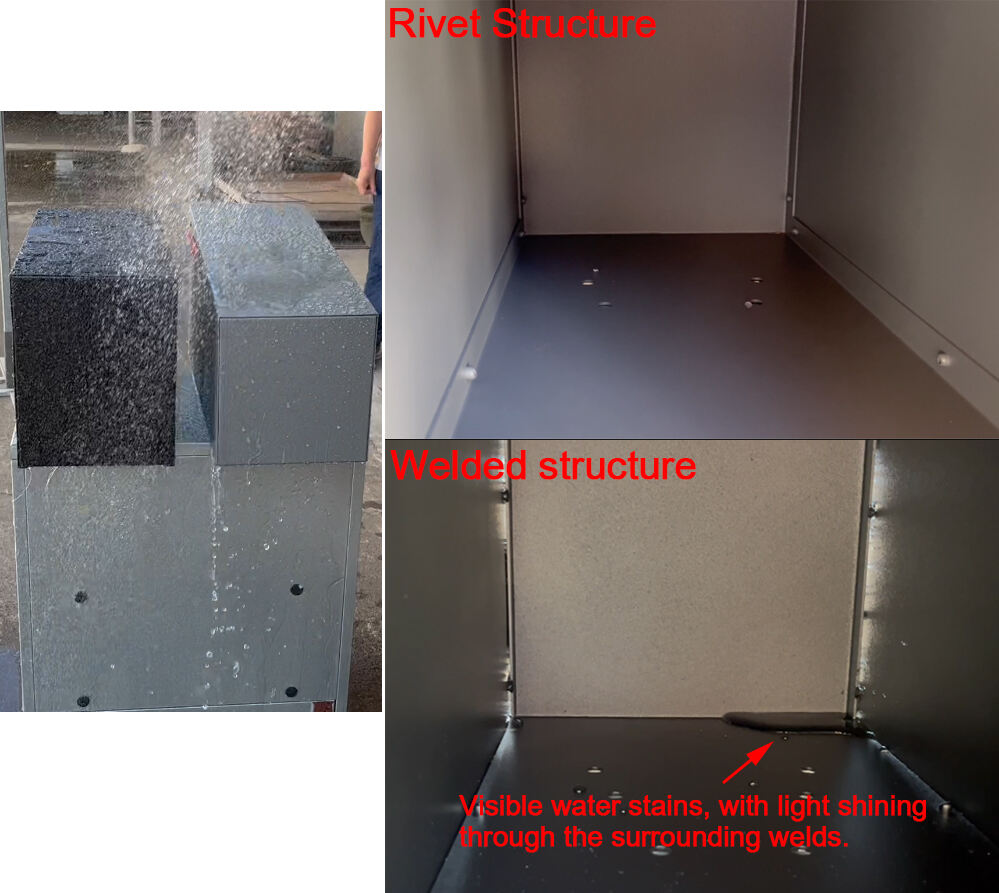

One used spot welding.

JDY used a full riveted structure.

In waterproof testing, the difference was clear:

Spot-welded seams showed visible leakage points. Riveted joints remained sealed and uniform.

This isn’t about welding skill alone. Welding fatigue, human inconsistency, and heat-affected zones all impact long-term quality. Riveted construction reduces variability, improves surface flatness, eliminates visible weld seams, lowers rust risk, and enhances appearance—especially for outdoor products.

👉 If you’d like to understand more about corrosion risks and process choices, see our article on [Why Parcel Boxes Rust—and How to Prevent It].

Another example came from Front Chute parcel box designs.

Some market products combine the delivery panel and anti-theft panel into a single piece. Visually clean—but functionally risky. In heavy rain, water naturally follows the panel surface straight into the storage compartment. Waterproofing options are extremely limited with this structure.

JDY uses a separated delivery panel and anti-theft panel design.

Even if rain enters the outer chamber, it is guided into pre-designed drainage channels, then expelled from the box—away from parcels.

Combined with waterproof bent edges and sealing strips, this structure significantly reduces the risk of wet parcels.

👉 For a deeper breakdown, you can read our guide on [Waterproof Parcel Box Structures and Rain Simulation Testing].

Whether you are an experienced procurement manager or a new e-commerce brand testing the market, one reality is the same: every wrong design decision costs time, money, and opportunity.

Working with a factory that has deep product and structural experience significantly reduces trial-and-error. Many issues—water ingress, rust points, anti-theft weaknesses, assembly tolerance—do not appear in drawings or renders. They only surface after real-world use, customer complaints, or warranty claims.

At JDY, our role goes beyond manufacturing. We help buyers avoid predictable mistakes before they happen.

That means advising on structure, materials, and processes based on how the product will actually be used—region, climate, installation method, and target price point.

For established B2B buyers, this shortens development cycles and improves consistency across batches.

For new brands or online sellers, it lowers the cost of market testing and reduces the risk of launching a product that looks right but fails in use.

In simple terms:

You don’t have to learn every lesson the hard way—because we already have.

This is why many of our clients start with one model, then gradually expand their range with confidence, knowing the foundation is technically sound.

After the visit, the clients confirmed a container order with JDY.

As we shook hands, we smiled and said:

“Your workday is officially over. Now you can enjoy traveling in China.”

They laughed. We meant it.

Because when the factory speaks for itself, decisions become easier.

If you’re evaluating suppliers, comparing samples, or planning factory visits, we’re happy to share what we’ve learned—openly and practically.

JDY focuses on details that protect your brand long after the shipment arrives.

Feel free to contact us or explore our technical articles for deeper insights.