Have you ever opened what looked like a perfectly fine parcel box — only to discover that the inside was rusting?

It seems counterintuitive, doesn’t it? Metal boxes are expected to rust on the outside where they’re exposed to rain and air, not on the inside.

So what’s actually happening here?

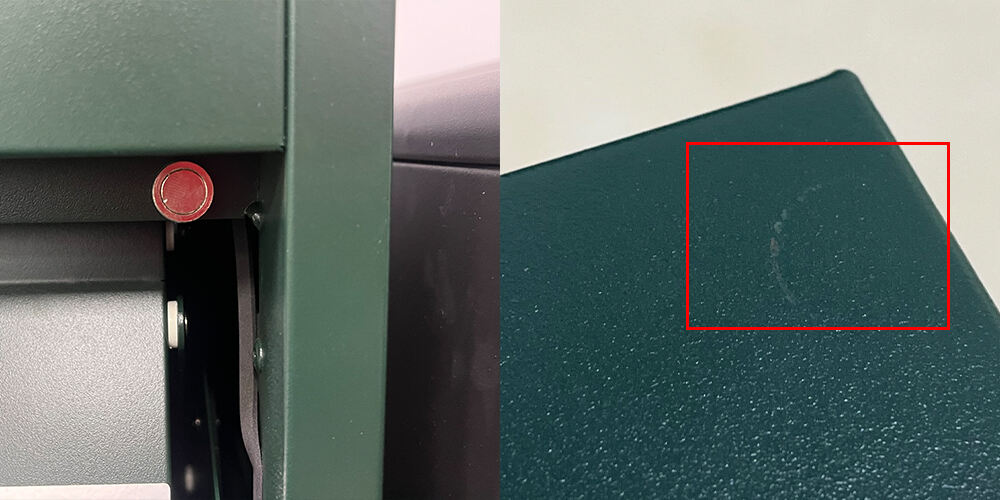

This was exactly the question a few of our customers raised. They shared photos showing that rust only appeared around three tiny points inside the parcel drop slot — nowhere else. At first glance, the material and powder coating were identical inside and out. The rusting pattern didn’t make sense.

Our engineers started by examining where the corrosion occurred. Each of the rusty spots lined up precisely with the magnetic contact points where the door closes.

As you might expect, magnets contain iron, which can corrode when exposed to moisture. But surprisingly, in this case, the magnets themselves were not rusting at all.

Instead, we found that the powder coating film on the door surface was being gradually worn down by the magnet’s repeated contact. Each time the door opened and closed, the tiny impact caused microscopic abrasions in the coating. Over years of use, these small scratches accumulated and weakened the protective layer, exposing bare metal underneath.

Once moisture found its way into the narrow gap between the magnet and door, water droplets tended to stay trapped there — not enough to cause visible leaks, but enough to create a perfect micro-environment for rust.

This meant the problem wasn’t the coating quality or the steel grade. It was the physical interaction between the magnet and the door, multiplied by time.

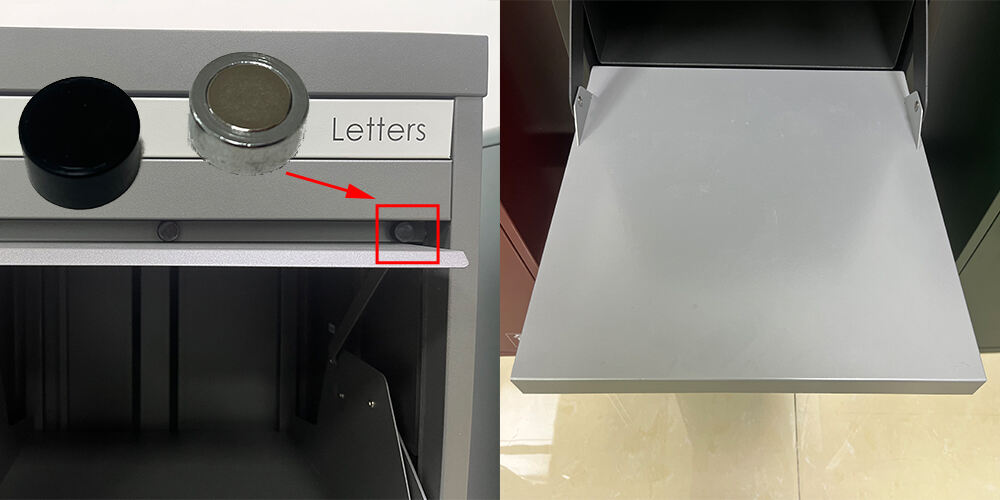

Once we understood the mechanism, we redesigned the magnetic contact system.

We added a thin silicone film around the magnet’s edge — a small detail that made a big difference.

The soft silicone layer acts as a cushion, preventing direct metal-to-metal contact.

The smooth surface helps protect the powder coating from abrasion.

It also reduces closing noise by nearly 50%, making the door action quieter and more refined.

Our tests confirmed that the magnetic force remained strong enough to keep the door securely closed, while the new design completely eliminated rust formation over time.

After months of real-world use, our clients reported zero recurrence of internal rust, even in high-humidity environments.

Rust may look like a minor cosmetic issue, but for us, it’s a matter of principle.

At JDY, we believe that every detail matters — especially the ones you can’t see.

Many parcel boxes on the market look similar at first glance. But longevity comes down to engineering — understanding how materials behave after years of exposure, movement, and use.

It’s the difference between a box that looks good for one season and one that performs flawlessly for ten years.

By rethinking even a small part like a magnet, we’ve made our parcel boxes quieter, smoother, and more resistant to time itself.

Because in manufacturing, perfection isn’t about the big things — it’s about mastering the details.

Looking for a quality parcel box manufacturer? Please contact us.

Hot News

Hot News2025-11-10

2015-06-01

2025-06-07

2025-03-31

2025-08-30

2025-08-11