Sustainable Packaging, Real-World Testing: How Our New Eco Materials Hold Up

A Greener Future Starts with Smarter Packaging

With environmental awareness growing worldwide, we’re stepping up to the challenge. As part of our sustainability mission, we've significantly reduced the use of foam and plastic in some of our product packaging. Instead, we're now using:

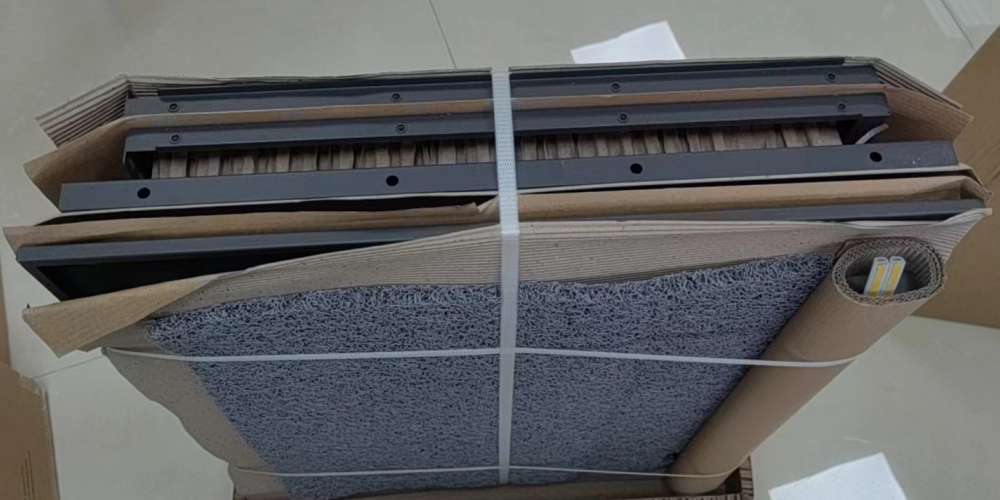

Honeycomb paper – a paper-based material bonded into a hexagonal structure for enhanced shock absorption(Below is a schematic diagram demonstrating impact resistance)

Kraft paper – durable, biodegradable, and eco-friendly

These materials don’t just align with our green values — they also need to do the job: protect your products during shipping.

So we put them to the test.

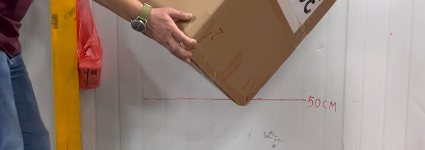

To evaluate the protective performance of our new packaging, we conducted a 50cm drop test simulating real-world parcel handling. The test specifically targeted high-impact zones:

Top corners

Edges

Flat surfaces

We tested two models:

3001V3 – a modular product with a detachable design

3007 – a single-piece product with integrated packaging

Model: 3001V3 (Detachable Structure)

Result: Passed with flying colors

Status: Structure remained intact, no visible deformation

Conclusion: Fully functional and shipment-ready

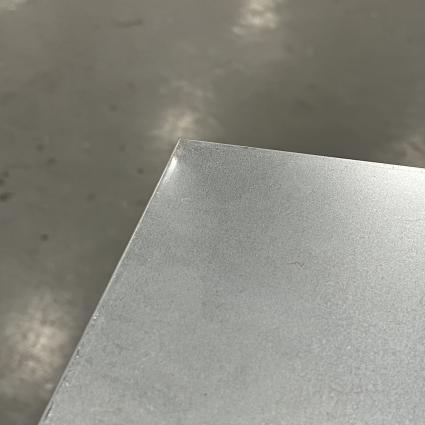

Model: 3007 (Single-Piece Structure)

Result: Passed

Status: Slight deformation on top surface, structure unaffected

Conclusion: No impact on usability

Final Takeaway

Eco-friendly packaging doesn’t mean compromising on protection. Our new honeycomb and kraft paper system stood up to the challenge, absorbing impacts while staying lightweight and sustainable.

We’ll keep pushing forward — smarter packaging, stronger protection, and a smaller footprint on the planet.

Hot News

Hot News2025-11-10

2015-06-01

2025-06-07

2025-03-31

2025-08-30

2025-08-11